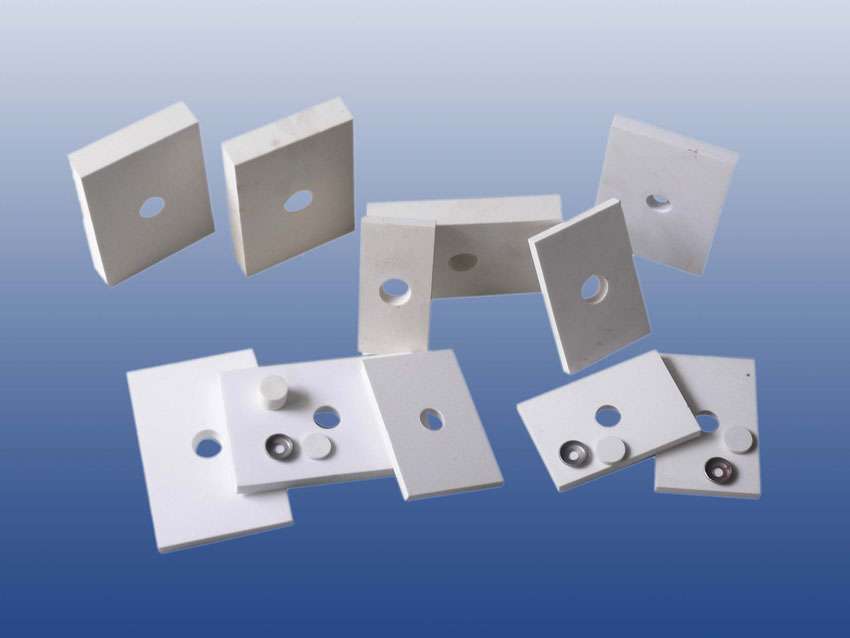

keramisk foring af aluminiumoxid

Alumina Ceramic Tile er høj slidstyrke, syre- og alklimodstand, forlænger effektivt udstyrets levetid og betragtes som det bedste valg af slidstærkt og korrosionsbeskyttende materiale; Slidstærk keramik er 266 gange end speciel mangan, 171,5 gange til højkromet støbejern; Hårdhed er meget højere end slidstærkt stål og rustfrit stål.

Application for this kind wear resistant lining: Oil, mining, steel and power industry.

Size Available(mm) for this kind abrasion resistant lining: Length x width x height

10 * 10 * 5/10

17.5 * 17.5 * 4/5/6/7

120 * 80 * 10/12.7/20

110 * 37/34 * 12

130 * 50/47 *12

150 * 60/57 * 12/10

150 * 100 * 50/25.4/12.7/6

100 * 100/50 * 25.4

Hextile: Customized

Trapezoidal Tile: Customized

Heatrotypic Tile: Customized.

Superior wear life in alumina can be attributed to these basic characteristics:

1 Individual alumina grains should be a fine size.

2 Have an even distribution throughout the body.

3 Glass matrix will have no porosity or crystallization.

4 Full adhesion to each alumina grain within the tile.

5 Tile density in relation to AL2O3 content.

6 Matrix components used and mix ratio in combination with firing temperature